|

| November 27, 2012 | Volume 08 Issue 44 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Wheels:

Jounce bumper gets the all-in-one treatment from DuPont

The jounce bumper is part of a vehicle's shock-absorber system, designed to absorb impact and dampen noise, vibration, and harshness (NVH).

DuPont Performance Polymers featured an innovative automotive jounce bumper component at the FAKUMA 2012 show Oct. 16-20 in Germany. The part is another feather in DuPont's cap when it comes to showing how design, materials, and processing (and a little technical help from your friends) can deliver added performance and lower cost.

The jounce bumper is part of a vehicle's shock-absorber system designed to absorb impact and dampen noise, vibration, and harshness (NVH).

DuPont, working with a team from injection blow molding specialist Ossberger, capitalized on the flexibility attributes of DuPont Hytrel thermoplastic elastomer and a unique Ossberger blow-molding technology to simplify and downsize the component count from four pieces that require subassembly to a single piece. This alone significantly reduced cost, size, and improved performance.

"Materials are critical in component design, and the best results happen when the three primary phases in product development -- design, materials, and processing -- converge," says Patrick Cazuc, automotive director Europe, DuPont Performance Polymers.

In developing this component, DuPont worked on the design using non-linear Finite Element Analysis (FEA) techniques and specialist software, as well as processing, including rapid prototyping and laboratory testing at the DuPont European Technical Centre. By using an Ossberger machine, the thickness profile was tightly controlled, facilitating optimum energy-absorbing properties with a maximum compression ratio.

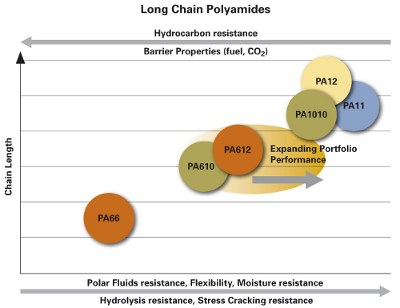

Long chain polyamides expand DuPont's portfolio performance.

The Hytrel jounce bumpers have been tested by automakers on a variety of vehicles over tens of thousands of miles. You can view a video of the testing here. According to an independent vehicle testing institute, "Jounce bumpers of Hytrel bring higher comfort and steering feedback, together with better road handling compared to PU [polyurethane] parts. Wheel rebound also is reduced with higher attenuation of low impacts. The front-axis roll angle also is reduced."

"The new Jounce Bumper is an example of DuPont listening to market needs and developing a superior solution, while providing all the necessary collaborative support needed to bring an idea from design to commercialization," says Cazuc. "More to come on this new development."

Source: DuPont

Published November 2012

Rate this article

View our terms of use and privacy policy